- Need Free Consultation ?

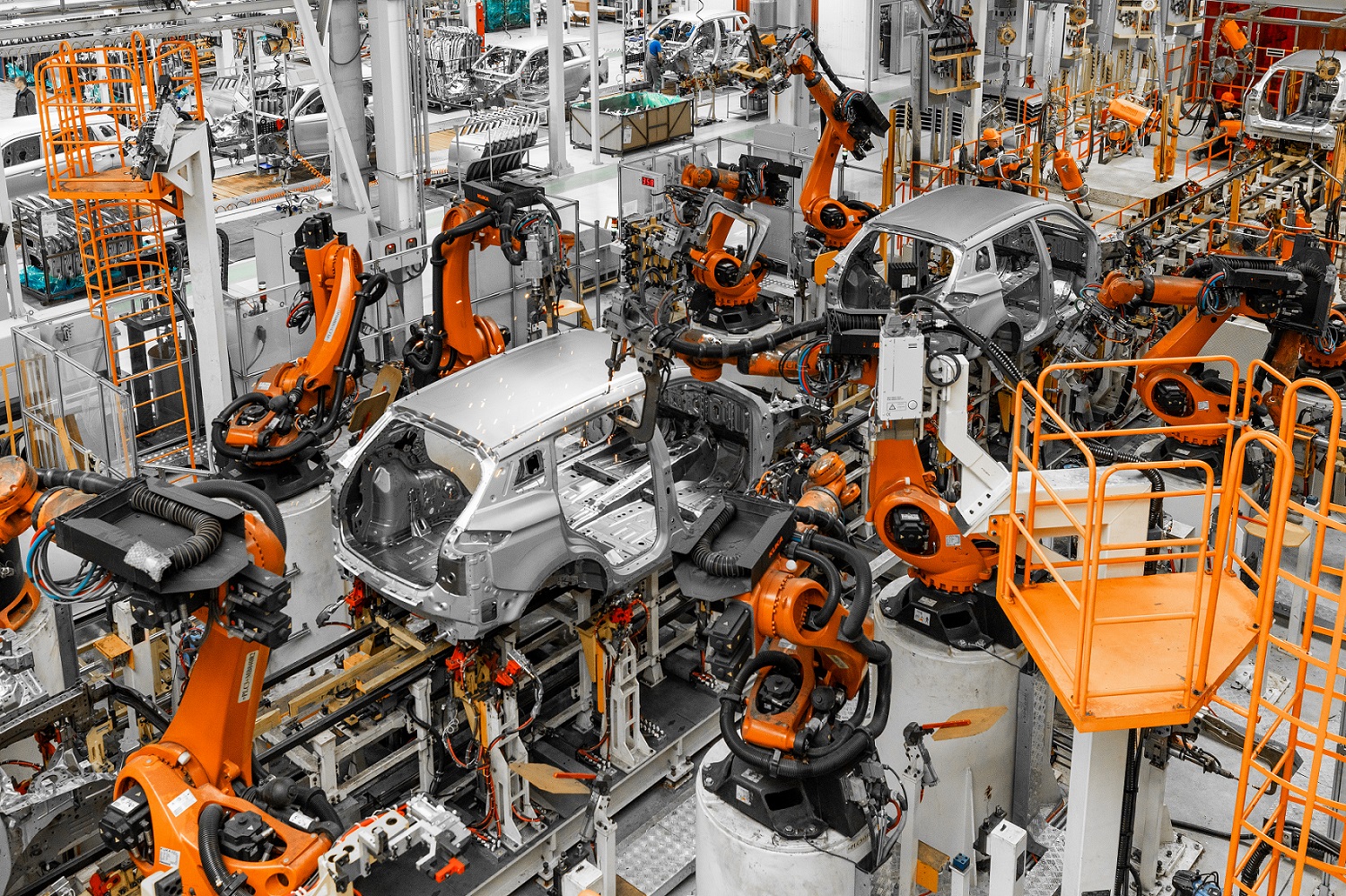

At Robtech Robotics, we understand the dynamic and fast-paced nature of the automotive industry. Our cutting-edge robotic and automation solutions are designed to enhance productivity, improve quality, and reduce costs across all stages of automotive manufacturing.

The automotive industry is continually evolving, driven by the need for increased efficiency, precision, and innovation. This sector faces constant pressure to adapt to new technologies, regulatory requirements, and customer expectations. Robtech Robotics offers state-of-the-art automation solutions tailored to meet the unique demands of automotive manufacturing. Our advanced technologies streamline production processes, enhance product quality, and enable manufacturers to stay ahead in a competitive market.

In today’s fast-paced environment, automotive manufacturers must optimize every aspect of their production lines to remain viable. Our automation solutions are designed to address these challenges head-on. By integrating sophisticated robotic systems, we help automotive manufacturers increase their operational efficiency and reduce the time-to-market for new vehicles. Our solutions ensure that each component is produced with the highest level of precision, reducing defects and improving the overall reliability of the finished product.

Streamline your assembly processes with the integration of robotic arms and automated guided vehicles (AGVs). These advanced systems work together to handle complex tasks, reduce manual labor, and significantly increase production efficiency. By automating repetitive and time-consuming tasks, assembly lines can achieve faster cycle times and higher throughput, leading to improved overall productivity.

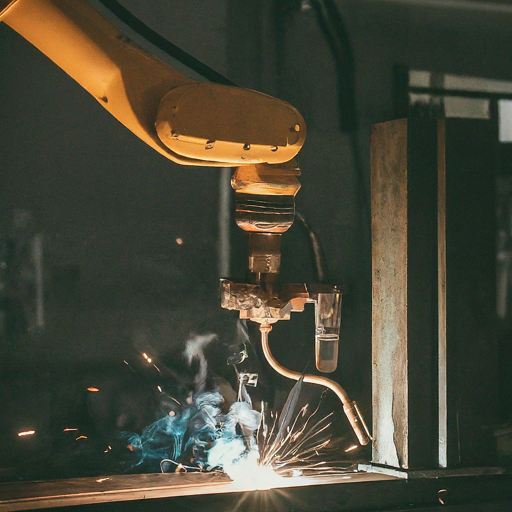

Enhance precision and consistency in welding and painting tasks with our state-of-the-art robotic systems. Automated welding robots ensure accurate welds with minimal defects, while robotic painting systems provide uniform coverage and finish quality. These technologies not only improve the quality of the final product but also reduce waste and rework, resulting in significant cost savings.

Strengthen your quality control processes with automated inspection systems that ensure product conformity and reliability. Our advanced inspection technologies use machine vision and sensors to detect defects, measure dimensions, and verify assembly accuracy. By automating inspection tasks, manufacturers can achieve higher standards of quality, reduce the risk of errors, and maintain consistent product excellence.

Robtech Robotics specializes in robotic welding systems that enhance precision and consistency in automotive manufacturing. Our systems support various welding techniques, including MIG, TIG, and spot welding, ensuring defect-free joints with minimal human intervention. With real-time monitoring and adaptive controls, our robots maintain optimal weld quality, even in complex conditions, reducing production time and costs while delivering cleaner, stronger, and more reliable welds.

Automate repetitive tasks to significantly cut cycle times and boost production rates efficiently.

Achieve higher precision and consistency in manufacturing, reducing defects and improving product quality.

Have questions or need support? We’re here to help. Reach out to us for customized automation solutions, technical assistance, or any inquiries. Our team is ready to assist you.

Robtech Robotics: Innovating automation with precision, quality, and sustainability.

+971 561969555

Info@robtechrobotics.com

Dubai, United Arab Emirates

Robtech Robotics: Innovating automation with precision, quality, and sustainability.

+62 478-2240-190

admin@support.com

Kapten Japa West ST. 1190 DPS, Bali

Copyright @2026, All Rights Reserved. Design By Technomantra India / Technomantra Global / Technomantra US / Technomantra Canada / Technomantra Local / Technomantra Australia