- Need Free Consultation ?

Battery production is a critical and rapidly evolving industry, driven by the increasing demand for energy storage solutions. Robtech Robotics offers cutting-edge automation technologies designed to optimize every stage of battery manufacturing, from assembly to quality control. Our solutions help manufacturers achieve higher efficiency, precision, and product quality in this highly competitive market.

Battery production requires high precision and efficiency to meet the growing demands of the energy storage market. Robtech Robotics provides advanced automation solutions that streamline production processes, reduce costs, and improve product quality. Our technologies are tailored to meet the unique challenges of battery manufacturing, ensuring reliable and consistent results.

With the rise of electric vehicles, renewable energy storage, and portable electronic devices, the demand for high-performance batteries has never been higher. At Robtech Robotics, we understand the critical importance of producing batteries that are both efficient and reliable. Our automation solutions are designed to handle every aspect of battery production, from assembly and welding to inspection and testing. By incorporating state-of-the-art robotics and advanced control systems, we help manufacturers achieve unparalleled precision, reduce material waste, and enhance overall production efficiency. Trust Robtech Robotics to provide the cutting-edge technology needed to stay competitive in the fast-paced battery industry.

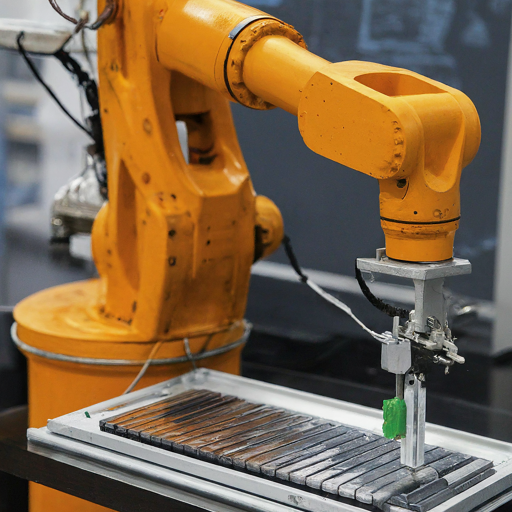

Streamline the assembly of battery cells and modules with precise and efficient robotic systems. Our automated assembly lines are equipped with advanced robotic arms that handle intricate tasks with high precision, significantly reducing human error and increasing production speed. These systems are capable of assembling various battery components, ensuring a seamless and efficient production process. By automating the assembly stage, manufacturers can achieve higher throughput, maintain consistent quality, and reduce labor costs.

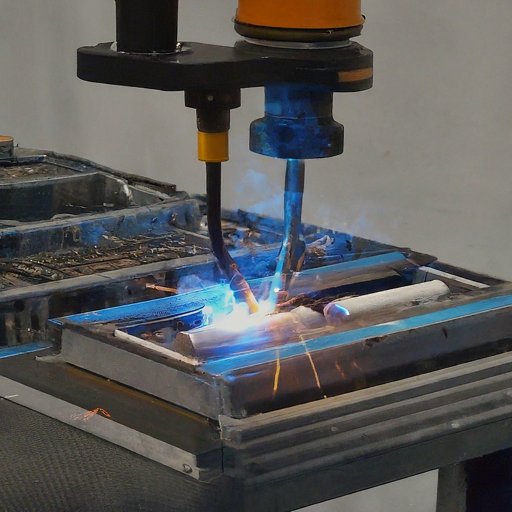

Enhance the accuracy and consistency of welding and sealing processes with advanced robotics. Our robotic welding systems provide precise welds that are critical for the integrity and performance of batteries. Whether it's spot welding, laser welding, or ultrasonic welding, our robots ensure consistent and high-quality joints. Additionally, our automated sealing technologies apply consistent and uniform seals, preventing leaks and ensuring the durability of battery packs. This level of precision in welding and sealing not only improves product quality but also extends the lifespan of batteries.

Implement automated inspection and testing systems to ensure product quality and conformity. Our inspection systems use advanced machine vision and sensor technologies to detect defects, measure dimensions, and verify the integrity of assembled batteries. Automated testing procedures, including electrical tests, thermal tests, and mechanical stress tests, are integrated into the production line to validate battery performance. By automating inspection and testing, manufacturers can ensure that each battery meets stringent quality standards, reducing the risk of defects and enhancing reliability.

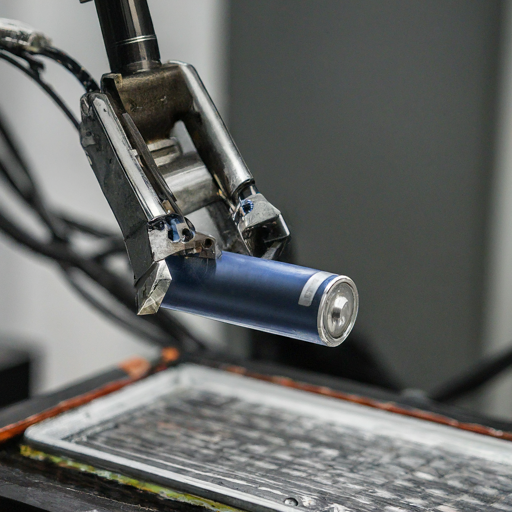

Optimize material handling within the production facility with advanced robotic systems. Our automation solutions include autonomous mobile robots (AMRs) and precision conveyor systems designed to transport raw materials, components, and finished products efficiently. These systems reduce manual handling, streamline the movement of items, and improve overall production flow. Automated material handling ensures timely delivery to production lines and minimizes bottlenecks, contributing to enhanced operational efficiency.

Lower operational costs through improved resource utilization and reduced labor expenses.

Minimize human error and enhance workplace safety with automation technologies.

Have questions or need support? We’re here to help. Reach out to us for customized automation solutions, technical assistance, or any inquiries. Our team is ready to assist you.

Robtech Robotics: Innovating automation with precision, quality, and sustainability.

+971 561969555

Info@robtechrobotics.com

Dubai, United Arab Emirates

Robtech Robotics: Innovating automation with precision, quality, and sustainability.

+62 478-2240-190

admin@support.com

Kapten Japa West ST. 1190 DPS, Bali

Copyright @2026, All Rights Reserved. Design By Technomantra India / Technomantra Global / Technomantra US / Technomantra Canada / Technomantra Local / Technomantra Australia