- Need Free Consultation ?

The electronics industry is at the forefront of technological innovation, requiring precise, reliable, and efficient manufacturing processes. Robtech Robotics provides cutting-edge automation solutions tailored to meet the complex demands of electronics manufacturing. Our advanced technologies streamline production, enhance quality, and boost productivity, helping manufacturers stay competitive in a rapidly evolving market.

Automation in the electronics industry is essential for managing the intricate and delicate processes involved in manufacturing electronic components and devices. The complexity of tasks such as surface mount technology (SMT) assembly, soldering, and inspection necessitates the use of advanced automation systems. By integrating automation, manufacturers can achieve higher levels of accuracy, ensuring that every component is placed correctly and every solder joint is flawless. This reduces defects and enhances the overall quality of the final product.

Robtech Robotics specializes in providing tailored automation solutions designed for the unique challenges of electronics manufacturing. Our cutting-edge systems handle high-speed production environments while maintaining unparalleled precision. By automating repetitive and labor-intensive tasks, our solutions help to significantly reduce material waste and operational costs. Advanced robotics and AI-driven inspection systems ensure consistent quality control throughout the production process. With Robtech Robotics, electronics manufacturers can streamline operations, improve efficiency, and remain competitive in a rapidly evolving market.

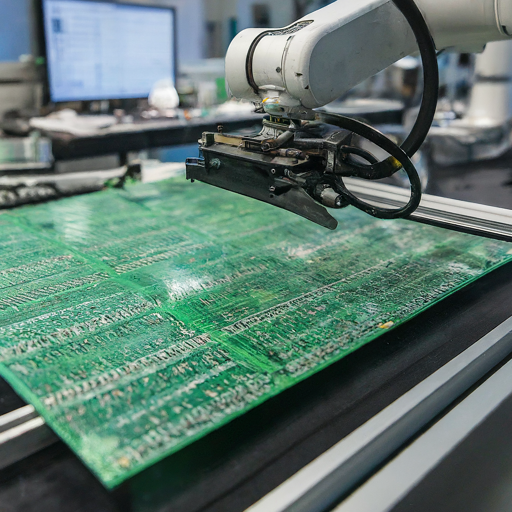

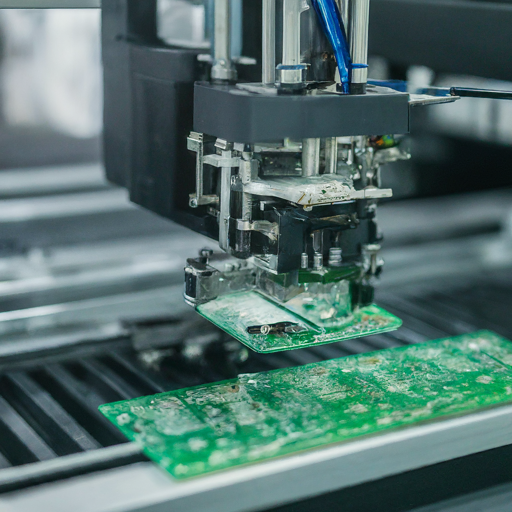

Automate the placement of electronic components onto printed circuit boards (PCBs) with high-speed SMT machines. These machines ensure precise alignment and secure placement of components, significantly improving production speed and reducing errors associated with manual assembly.

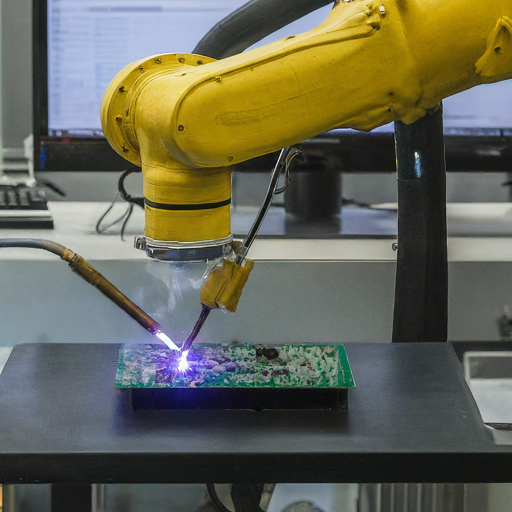

nsure precise and reliable solder joints with automated robotic soldering systems. These systems provide consistent soldering quality by controlling temperature, speed, and pressure, which reduces the risk of defects such as cold solder joints or bridging, thereby enhancing the durability and functionality of electronic devices.

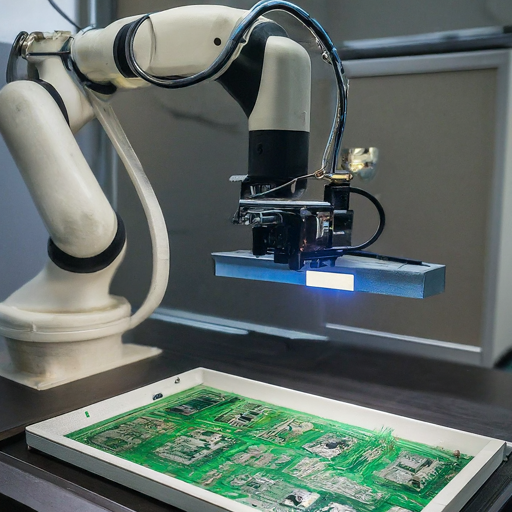

Implement advanced inspection systems for quality control, using machine vision and AI for defect detection. These systems can quickly and accurately identify issues such as misaligned components, soldering defects, and other anomalies, ensuring that only high-quality products proceed to the next stage of production.

Optimize the movement of materials and finished products with autonomous mobile robots (AMRs) and conveyor systems. These automation solutions streamline the logistics process within manufacturing facilities, reducing handling time, minimizing human error, and improving overall operational efficiency by ensuring materials are always in the right place at the right time.Robtech Robotics' tailored solutions for the electronics industry not only enhance production capabilities but also ensure the highest standards of quality and reliability, essential for maintaining a competitive edge in the market.

Automate repetitive and time-consuming tasks to boost production rates and meet market demands.

Ensure uniformity and reliability in every product with precise and repeatable automated processes.

Have questions or need support? We’re here to help. Reach out to us for customized automation solutions, technical assistance, or any inquiries. Our team is ready to assist you.

Robtech Robotics: Innovating automation with precision, quality, and sustainability.

+971 561969555

Info@robtechrobotics.com

Dubai, United Arab Emirates

Robtech Robotics: Innovating automation with precision, quality, and sustainability.

+62 478-2240-190

admin@support.com

Kapten Japa West ST. 1190 DPS, Bali

Copyright @2026, All Rights Reserved. Design By Technomantra India / Technomantra Global / Technomantra US / Technomantra Canada / Technomantra Local / Technomantra Australia